High precision positioning device for optical calibration

Task

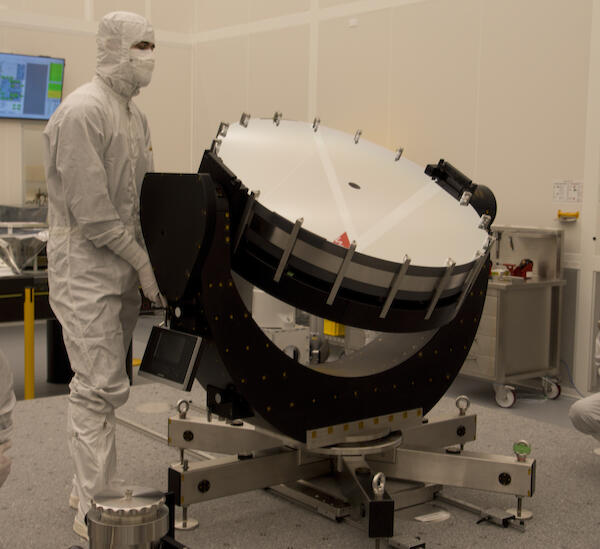

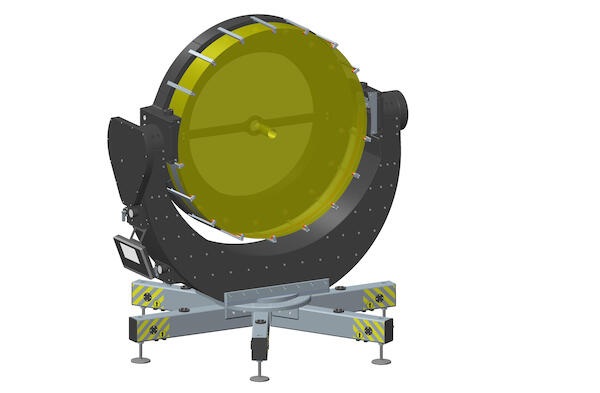

A mirror with a diameter of 1,080 mm is to be positioned in two axes to ± 2 arcsec by hand. The mirror weighs 315 kg and its own weight already curves the plane surface beyond the specification. The mirror must be suspended so that the curvature of the mirror surface due to its own weight does not exceed 15 nanometers at the different opteration positions.

Manual adjustment must be possible with a gear change between fast and slow. A fine adjustment of 1 arcsec is the target.

CEMEC service

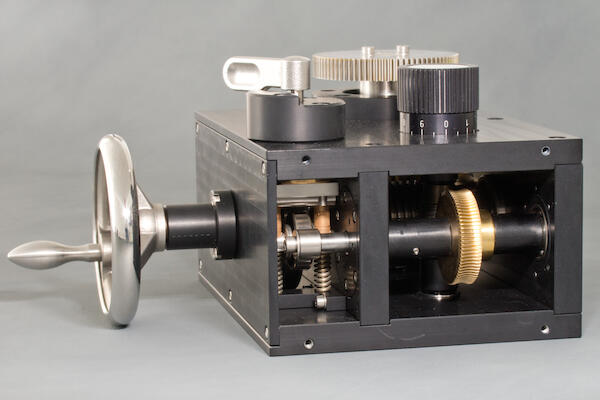

Manual transmission with two reduction stages for particularly smooth running with low movements

CEMEC developed the concept, provided the complete development of the mechanical parts with the interfaces to the mirror. The work package included the structural and thermal calculation to guarantee the accuracies and thermal behavior in the operation area. The feasibility of the mirror assembly including the lifting equipment for the mirror.

Manufacturing design according to ECSS standards, documentation with all phases and control sections (PDR, CDR, TRR....). Final documentation with operating instructions, maintenance and storage instructions. From the initial solution to the transport box - all from a single source.

Assembled, tested and packed in ISO 7 clean room.CEMEC

Manufacturing

Manufacturing of all components on our 5-axis / 3-axis and wire EDM machines.

Manufacturing of all hardware, including integrated bearings and gear parts.

CEMEC commissioning

The mirror system was delivered as a complete package:

- Positioning device mirror

- Special hoist for the mirror

- Rail lifting system for moving the unit up to 2.2 metres

- Special crane claw for safe transport of the mirror

- Special transport box

Final cleaning of the Sital mirror in the ISO 5 clean room

Transport to the positioning unit