Flsh forging

Development of a process for forging small components

Task

Components in a diameter range between 0.3 mm and 20 mm are to be given a forged head that can be produced without reworking if possible. Usually, large presses with up to 30 tons of pressure are used for this purpose.

Innovation

Test part with perfect drop-forged contour without additional reworking

CEMEC developed a process that can maintain the forging at a uniformly high temperature during deformation at extreme speed. The speed is extremely high during the forging process. Despite the high requirements, the components were manufactured with only 250 watts of drive power.

Realization

Test facility for flash forging of parts up to 500 grams unit weight

CEMEC invented the process, developed the process and built the corresponding test machine for it.

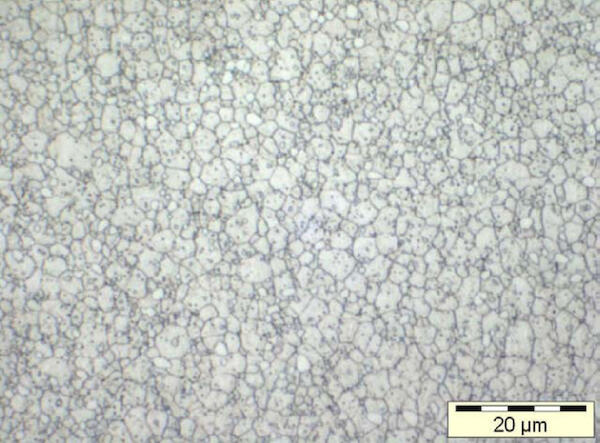

The results of the metallurgical tests show extremely good values for grain sizes, distribution of carbites and a high degree of die shaping during forging. The forging force is very finely adjustable and can be easily matched to the component.