Company tour

Optimal working environment

Take advantage of our facilities! CEMEC Facilities has been designed for the smooth flow and optimal dovetailing of development and production.

The 2018 finished expansion of the production hall and the modernization of the office area provide an excellent basis and plenty of space to realize a wide variety of tasks under ideal conditions.

Manufacturing

850m² of manufacturing area and a further 200m² of storage space provide generous areas that can be used flexibly for optimal order processing.

Exclusive space is also available upon request, which can then be used exclusively for your customer project.

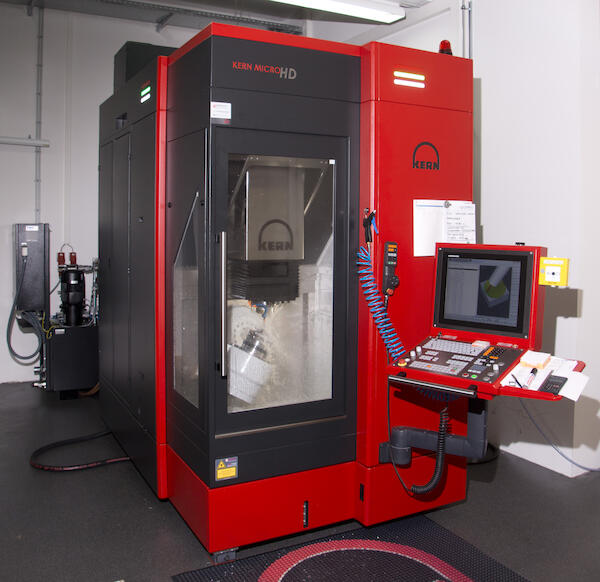

Precision manufacturing

Our high-precision 5-axis milling machine is located in a specially air-conditioned room. Here we can realize flatness and parallelism better 1 µm by milling. Spatial accuracy better 2 µm are achievable. Reflective surfaces without repolishing are highlights that create new possibilities and space for ideas.

Clean room with 3D measuring technology

Our ISO 7 clean room with 56m² and the separable class ISO-5 area with 22m² represent the quality standards with which components and assemblies can be measured and assembled.

Analyses and measurements

Physical measurements, long-term measurements are carried out in a specially equipped room. Work with vacuum technology and appropriate measurement equipment, work under nitrogen and ISO-3 environment are realized in shielded and extra filtered boxes.

Temperature simulations up to 1300 °C are possible for components up to 500 x 500 x 500 mm³.